Comparison of the process and characteristics of the three types of PET containers!

According to different production methods, PET containers can be divided into two categories: PET blow molded containers and PET thermoformed containers. Among PET blow molded containers, there are PET direct extrusion blow molded containers and PET biaxially stretched blow molded containers. In thermoformed containers, there are APET containers (amorphous PET sheet thermoformed containers) and CPET containers (crystalline PET sheet thermoformed containers).

1. The process and characteristics of PET direct extrusion blow molding container

It is made of special high-viscosity PET resin through conventional extrusion blow molding process, and has been used in small containers such as eye drops. Since the production of PET direct blow molded containers requires the use of specific high-viscosity PET resins, the raw material costs are relatively high, and the prepared containers have no special advantages (mechanical strength and barrier properties are worse than PET biaxially stretched blow molded containers). With the improvement and advancement of the production process and equipment of PET biaxially stretched bottles, the production of directly extruded PET bottles has become rare.

2. Process and characteristics of PET two-way stretch blow molding container

PET biaxially stretched blow molded containers are the main varieties of PET containers, and occupy a large proportion of PET containers. For example, in the United States, PET biaxially stretched blow molded bottles account for more than 90% of the entire PET container volume, and there are similarities in my country. Case.

The production process of PET biaxially stretched blow-molded bottles is usually to first use injection molding to prepare test-tube PET parisons, and then cool and heat (or temperature adjustment treatment) to reach a temperature suitable for blow molding. The rod is stretched longitudinally and blow molded with compressed air to make the final product. According to the different configuration of the parison manufacturing and stretch blow molding devices, PET stretch blow molding has another one-step method (the two devices for preform manufacturing and blow molding are configured in the same molding equipment, and PET is completed from pellets to products in the same equipment. ) And two-step method (preform molding and stretch blow molding are carried out in two equipment respectively). No matter which molding method is used, the current production and application of PET biaxially stretched blow molded bottles are mainly small bottles with a capacity of less than 1.5L, and the volume of the largest PET biaxially stretched blow molded bottle is only about 20L. The two-way stretch blow molding method can be used to blow small-mouth bottles or wide-mouth bottles to meet the needs of different packaging. At present, small-mouth PET two-way stretch bottles are the most widely used.

3. Process and characteristics of APET container

It is made of non-crystalline PET (APET) sheet by thermoforming, so only open containers such as boxes, cups and plates can be made. APE has molding properties that are very similar to that of PVC sheets. The vacuum molding equipment, molds and molding processes used in the molding of PVC sheets can be used in the molding of APET sheets intact, and APET containers have the same high transparency as PVC containers. , High gloss and other advantages, but also has good environmental adaptability that PVC containers do not have. Therefore, APET containers are considered to be an ideal substitute for PVC sheet thermoformed containers.

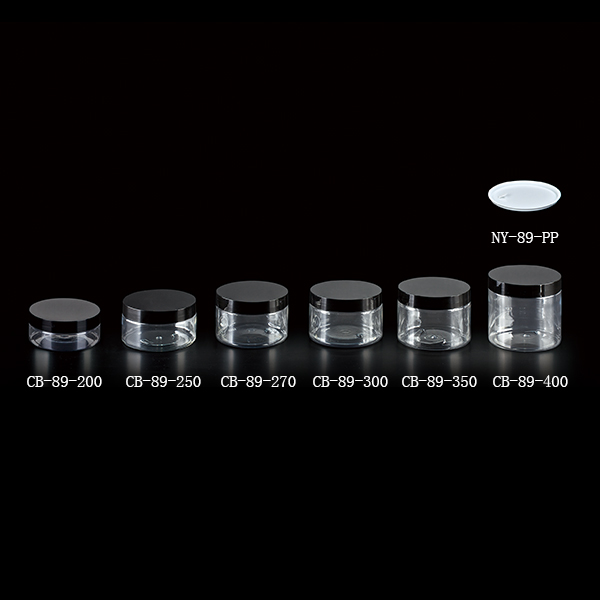

Wellpac started in October, 2008 with PET bottles & jars, but now PET here means more.Range from heavy wall PET jar, PP jar, closure, foaming pump as well PET bottle.